Design and R & D

Ansa Tech boasts a prestigious technical center, able to develop complete exhaust systems. Thanks to the competence and experience of highly qualified staff, it provides a consultancy and support service to the customer, using the most modern calculation programs:

CAD

- Creo Parametric

- Catia V5

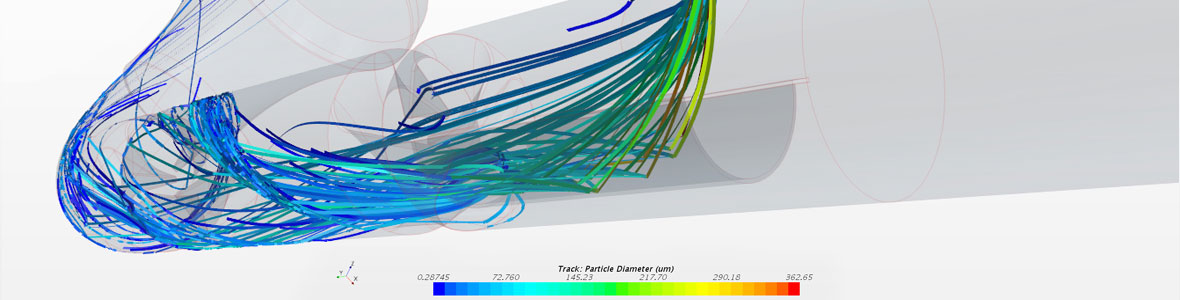

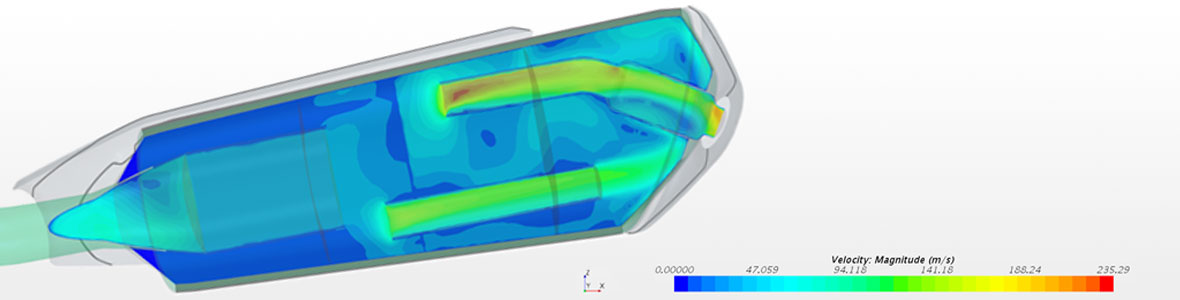

CAE

- acoustic and emissions: GT-Power

- CFD: Star-CD, Star-CCM +

- FEA: MSC-Nastran

Testing

Ansa Tech performs tests and controls for the monitoring and certification of products and production processes and among these tests they are able to carry out:

– Hot Vibrating Bench for the duration and qualification of components

– Dynamometric test bench with thermography

– Acoustics: integrated B & K system

– Sound quality: B & K torso, real time measurement of psychoacoustic parameters and filtration

– Three-dimensional laser optical scanning system

Prototyping

Highly qualified staff create soft tooling, prototypes and initial samples

Time to market is a key factor during the development of a project: in ANSA TECH we use the concurrent engineering method, realizing the necessary, soft tooling and rapid prototyping representative of the performance and the final appearance of the product.

All product development and co-design activities are conducted: from the initial idea of the customer to the delivery of the product. Our group of engineers is able to follow the customer assisting him to find the best solution with the best technology.